MITUTOYO-Contour and Surface Roughness Measuring Systems FORMTRACER Avant Series | JSR GROUP

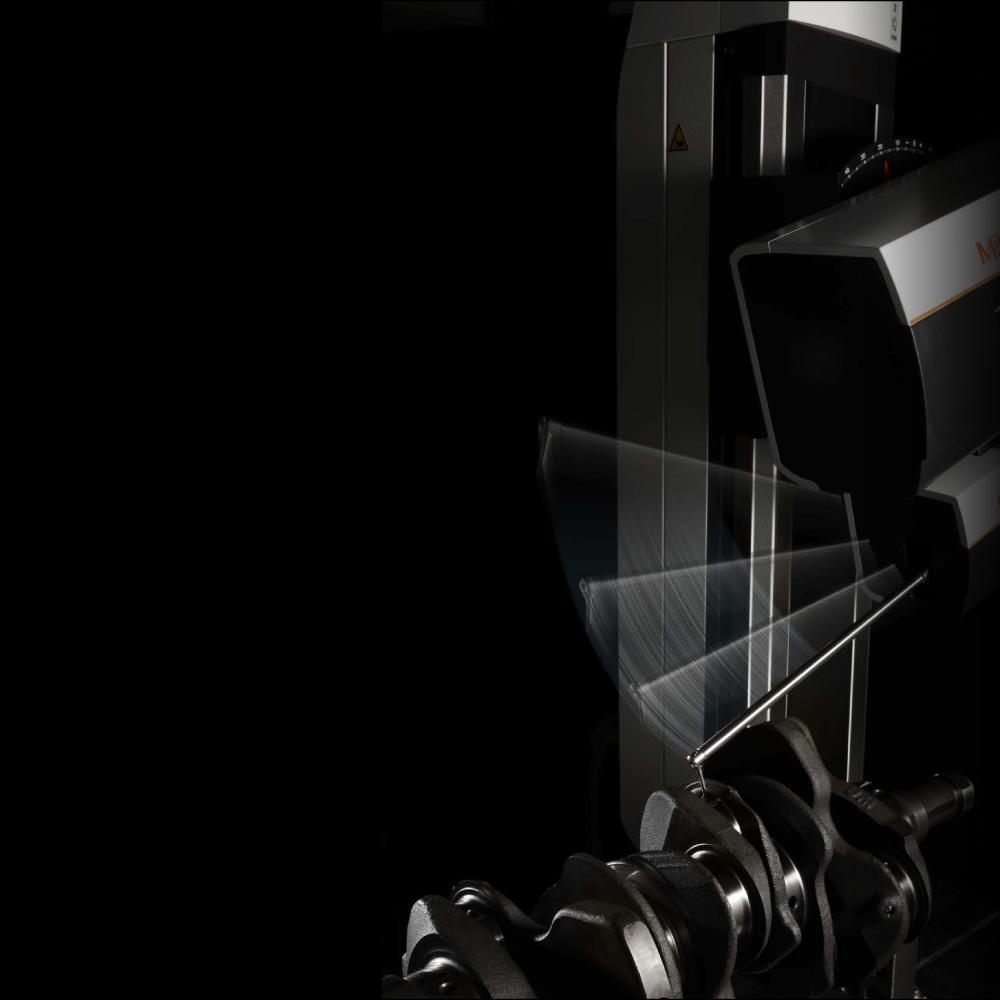

Contour and Surface Roughness Measuring Systems FORMTRACER Avant Series

FORMTRACER Avant SERIES

Contour and Surface Roughness Measur ing Systems

Speed and operability like never before

A revolutionary measuring system that defies conventional thinking.

The hybrid measuring system “FORMTRACER Avant Series" allows for measurements of both contour and surface roughness features. Equipped with “speed” enabling higher measurement efficiency, “operability” with automation and a wide variety of features, and expandability which offers upgrading to a complex system by incorporating optional detectors, this revolutionary measuring system defies conventional thinking.

|

|

CONTRACERContour Continuous upper/lower direction measurement combined with a measurement adjustable feature*, enables the continuous measurement of upper and lower face contours, including the effective diameter of screw-threads.The selectable measuring force feature* eliminates the need to set the measuring force by exchanging weights or switching orientation. Mounting an arm onto the Z1-axis contour detector via a magnet-type one-touch attachment/detachment system greatly improves the efficiency of contour measurement. |

|

|

VARIATION |

|

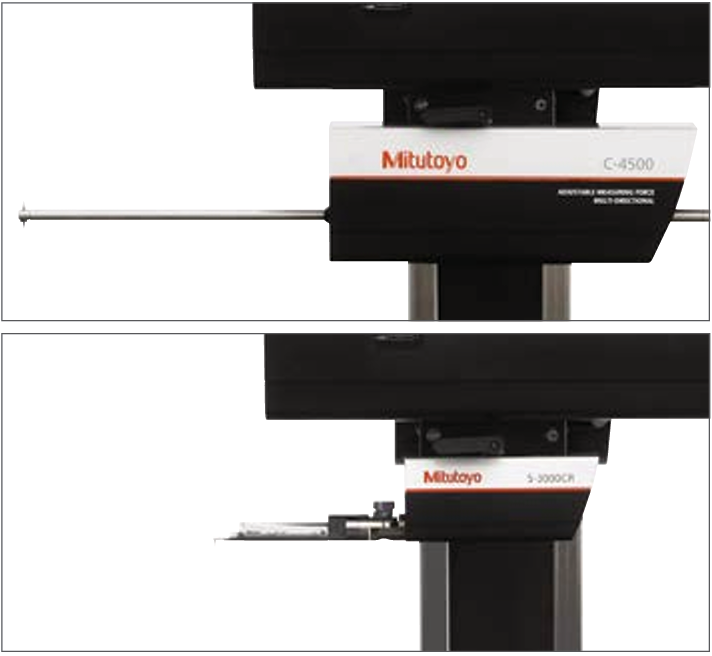

SURFTESTSurface roughness Compliant with JIS, ISO, ANSI, VDA, and other industrial surface roughness standards. Rapid movement of the measuring unit, combined with optional accessories to automate leveling of the measuring surface during setup prior to measurement, shortens measurement time and reduces the burden placed on the operator. |

|

VARIATION

|

A feature-rich lineup covers every purpose.

This single machine can measure contours and surface roughness.

Just by integrating a detector with a base system comprising FTA-S4C3000/4000 (contour instrument) and FTA-S4S3000 (surface roughness tester), it is possible to upgrade a contour instrument or surface roughness tester to a complex system, from a general-purpose contour instrument to a high-precision contour instrument. Three types of surface roughness detector holders can be added for a wider range of surface roughness measurements. Other than the addition of detectors, Mitutoyo provides a choice of 100/200 mm-type drive units, high-column instruments, and large-sized base instruments, as standard.

HIGH-SPEED“Speed-up” greatly increases throughput. FORMTRACER Avant Series boasts best-in-class drive speed for both drive unit and column axis along with |

Best-in-class drive-speed

High drive-speed drastically reduces the measurement time

X-axis (drive unit): 80 mm/s (MAX) Z2-axis (column vertical movement): 30 mm/s (MAX) Speed-up of the movement enables reduction of the total measurement time.

Reduction of the total measurement time

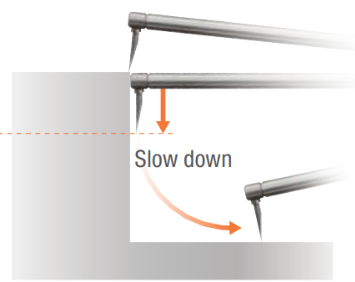

| The stroke (retraction) speed is improved by approx. three times compared to conventional models; meanwhile, the speed when the stylus goes down to touch a workpiece becomes slower in consideration of safety. The measuring system automatically detects the workpiece contact, then immediately moves into standby mode for the start of measurement approximately three times faster than a conventional model, for a drastic improvement in measuring efficiency. |

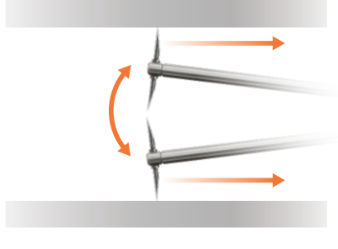

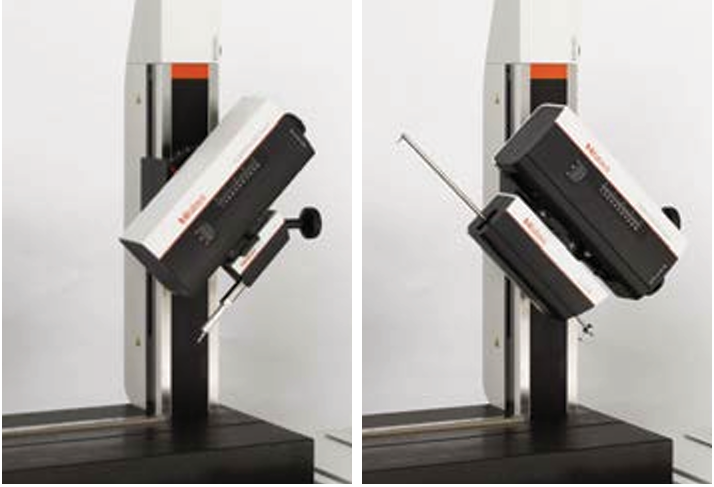

WORKABILITYRemarkably improved workability with outstanding features This cable-less system is designed to eliminate any risk of abrasion and guarantees trouble free, high-speed operation. The X-axis drive unit has a wide inclination range of +/- 45° allowing incline features on workpieces to be measured without added fixtures.Additionally, the detector can be replaced without turning power off, a positioning pin ensures accurate placement and software automatically detects the exchange to make it seamless and improve work efficiency |

|

|

X-axis incl inable drive unit To measure inclined surfaces efficiently, an X-axis inclinable drive unit which can measure surfaces within a range of ±45° is mounted. When mounting the contour detector C-4500, the measuring force can be varied in 5 steps by using the software provided (FORMTRACEPAK), eliminating the need to adjust the measuring force by switching weights or through positional adjustment. This system can also maintain the specified measuring force even when inclined. |

|

|

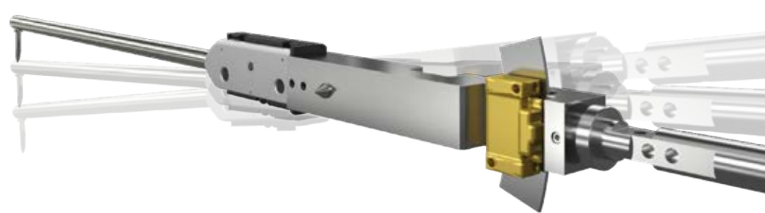

Arc scale The system features a built-in precision arc scale that allows the circular trajectory of the stylus tip to be read directly, eliminating the need for an arc direct conversion mechanism, which often causes measurement error on the detector. It allows precision measurement over a wide range even if the arm is not in the horizontal attitude. You can perform precision measurement without worrying about the measurement range. |

|

|

Cable-less All detector and drive unit cables are housed inside the main unit to eliminate any risk of abrasion or snagging and guarantee precision measurement and rapid movement. |

|

|

Hot swapping No need to turn the controller power off when replacing the contour detector or roughness detector; moreover, the tool-less replacement mechanism (thumb-turn clamp) greatly helps to reduce the replacement time by approx. 1/4 (approx. 30 seconds) compared to a conventional model. Further, positioning using the guide pin improves repeatability when replacing detectors and allows efficient operation of the automatic measuring program.

|

|

WORKABILITYOptimized measurement features depending on characteristics of workpieces Functions such as upper/lower surface continuous measurement, changing of measuring direction and setting of measuring force using a dual-sided stylus through the software remarkably improves the measurement capabilities. The stylus-drop detection feature immediately stops operation when it detects a sudden drop preventing damage to stylus or machine. It can also hold a position to measure an interrupted surface without using a mechanical stopper. Other features enable accurate and safe measurements in accordance with the characteristics of a workpiece. |

|

|

Upper/lower surface continuous measurement

|

Upper/lower surfaces can be measured continuously by using Mitutoyo’s double-sided conical stylus. This continuous measurement data can be used to facilitate analysis of features that were difficult to measure before, such as the effective diameter of an internal screw-thread. The collision monitoring feature for the magnet arm and the detector cover ensures safe measurement even during high-speed movement, in addition, optional accessories for automatic measurement automate processes from the setup to the measurement

|

|

Stylus drop detection feature

|

Detects sudden drop of the stylus from a measurement surface and stops the measurement operation; also, it controls the dropping rate to avoid breakage of stylus.

Detecting a sudden drop |

|

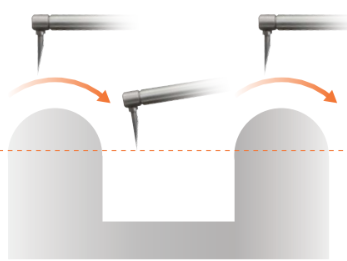

Continuous cut-out measurement feature

|

The detector hold position can be registered, allowingmeasurement to be performed without dropping below the preset position. This feature allows continuous measurement of interrupted surface features on workpieces without needing to use mechanical stoppers.

Drop prevention |

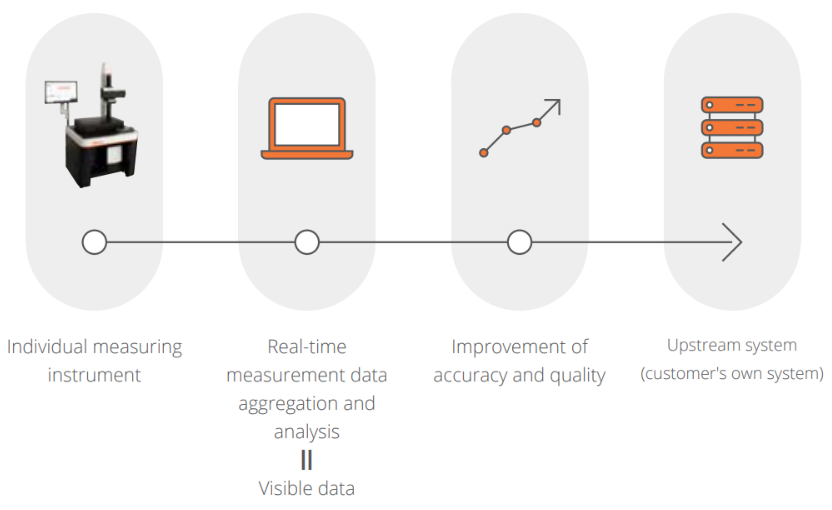

SOFTWARE

Support for an integration of management and sharing of measurement data to assist in the visualization of high quality

FORMTRACEPAK is equipped with a wide variety of features, such as control of the contour and surface roughnessmeasuring systems, data analysis and comparison and report generation. MCubeMap visualizes the analysis data in detail by using various graphical technologies. MeasurLink integrates measured data to a server via a networking system. Mitutoyo supports the recognition of quality improvement by minimizing product defects in production through integrating management and sharing of data.

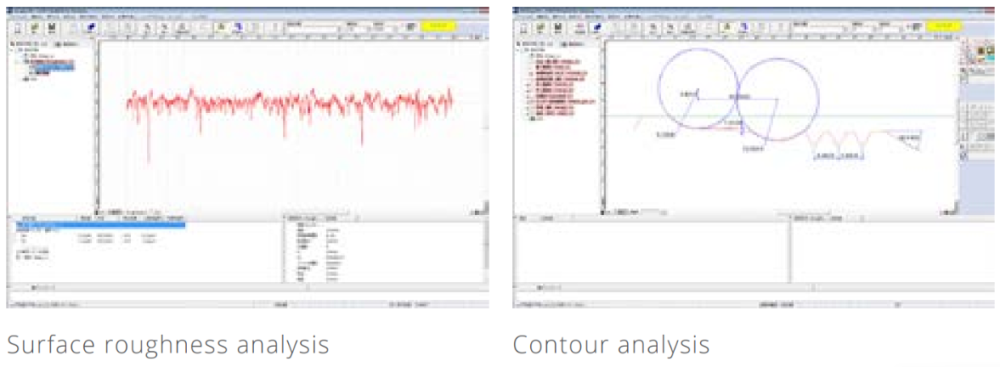

FORMTRACEPAK

< Surface property analysis program >

FORMTRACEPAK features offer total support for controlling the measuring system, surface roughness analysis, contour analysis, contour tolerancing, and inspection report creation.

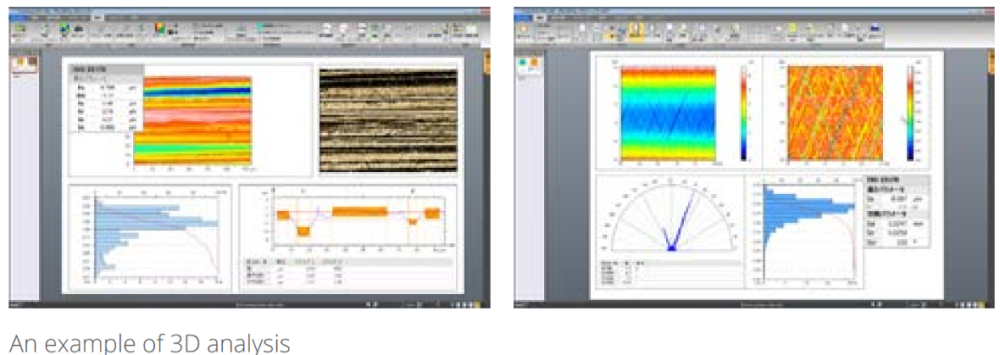

MCubeMap

< 3 D surface property analyzing software >

Parameter analysis is available for not only the vertical directions of Sa and Sq, but also spaces, compounds, and features. A wide variety of graphical technologies help visualize the analyzed data in detail.

Note: The Y-axis table for 3D measurement is required separately

MeasurLink

< Measurement Data Network System >

MeasurLink networks each measuring system and aggregates the measurement data in a server. The real-time aggregation enables “Visible quality” meaning the unified management and sharing of information relevant to quality.

DESIGN

Coexistence of structure and functional vision with no compromise to details

Aesthetics, functional logic and reliable measurement accuracy. We sought a product design encompassing all of these. Combining perfection, a desire to design with no compromise to details and functional logic, we sought to provide both operability and innovation. In addition to coloring, the new design adds improvements and ingenious features that considers the whole product structure and makes it easier to use.

OPTIONS

Optional accessories for automatic measurement

Mitutoyo offers a wide variety of optional accessories supporting the major reduction of total measurement time, from setup and measurement to evaluation, by enabling quicker implementation of operations, such as measurement of multiple points, alignment of cylindrical workpieces and leveling for surface roughness measurement.

|

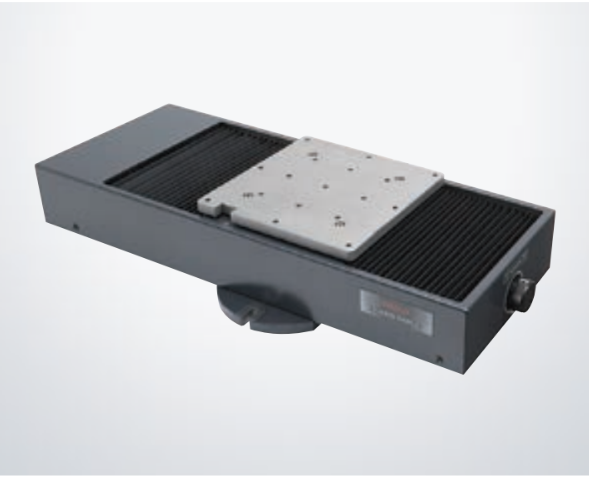

Y-axis table 178-097 Enables efficient, automatic measurement of multiple aligned workpieces and multiple points on a single surface.

|

Travel range: 200 mm Resolution: 0.05 µm Positioning accuracy: ±3 µm Drive speed: Max 80 mm/s Maximum load: 50 kg Mass: 28 kg |

|

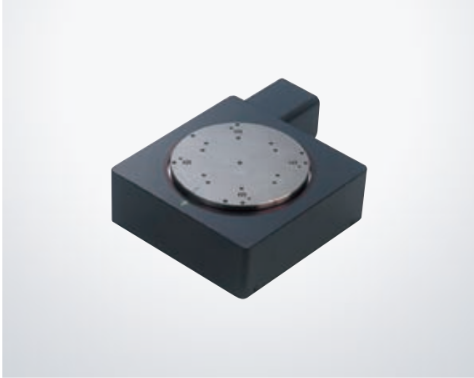

Rotary table θ1-axis table 12AAD975 For efficient measurement in the axial/ transverse directions. When measuring a cylindrical workpiece, automatic alignment can be performed in combination with the Y-axis table. |

Displacement: 360° |

|

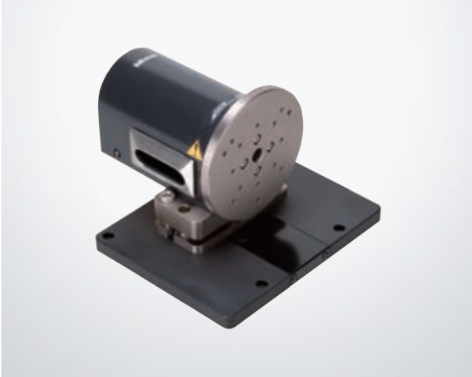

Rotary table θ2-axis unit 178-078 You can measure multiple points on a cylindrical workpiece and automate front/rear-side measurement. (* θ2-axis mounting plate <Option: 12AAE718> is required when directly installing on the base of the FORMTRACER Avant.) |

Displacement: 360°

|

|

Auto leveling table 178-087 This table performs fully automatic leveling adjustment roughness measurement surfaces at the start of measurement. Full automation ensures rapid measurement regardless of the skill level of the operator. |

Inclination adjustment angle: ±2°

|

|

Drive unit DAT unit 178-050 This optional unit supports leveling of measurement surfaces by inclining the drive unit. This makes leveling easy when working with large workpieces that are hard to place on the auto leveling |

Inclination range: ±1.5°

|

|

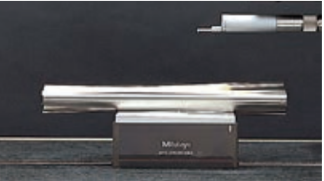

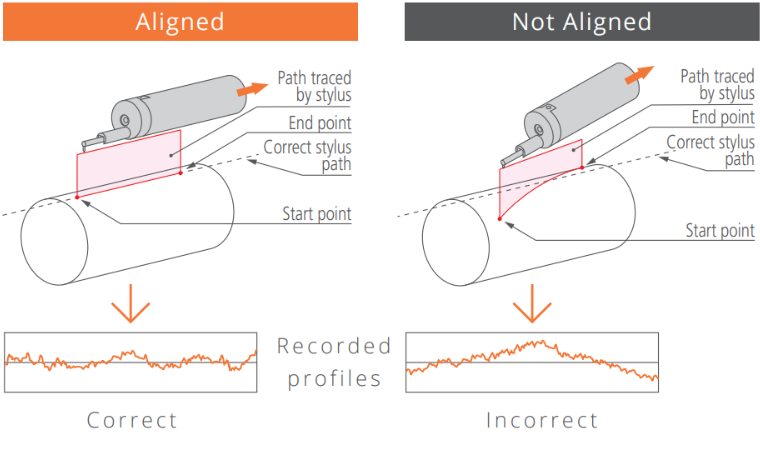

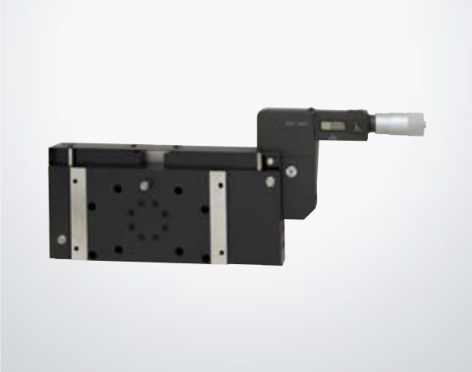

3-axis adjustment table | 178-047 This table makes the adjustments required when measuring cylindrical surfaces. The corrections for the pitch angle and the swivel angle are determined from a preliminary measurement and the Digimatic micrometers are adjusted accordingly. A flat-surfaced workpiece can also be leveled with this table. By using Mitutoyo’s 3-axis adjustment table, the workpiece can be aligned and leveled easily, simply by following the FORMTRACEPAK guidance.

|

|

Centering chuck (ring operated) | 211-032

This chuck is useful when measuring small workpieces. You can easily clamp them with its knurled ring. Holding range: |

Micro-chuck | 211-031

This chuck is suitable for clamping extra-small diameter workpieces (φ1 mm or less), which cannot be retained with the centering chuck. Holding range:OD: φ0.2 - φ1.5 mm |

APPLICATION

Efficient precision measurement for practically any workpiece

FORMTRACER Avant Series has applications supporting measurements for a wide variety of workpieces. For example, a part-program (automatic measuring program) creation support key equipped with the remote BOX allows rapid creation of programs, and the contour sensor allows immediate measurement by creating a measurement-ready state once the sensor contacts a workpiece. Further, this series features stylus-up speed three times faster than conventional models, and each axis movement speed is fast, too. By combining these elements into a single system, efficient and accurate measurements are realized.

|

PET bottle Preform measurement

The thread of a familiar PET bottle requires precision measurement,since leaks will occur if it is too loose, or the cap cannot be tightened if it is too tight. The “sectional form of thread” of such PET bottles can be measured without cutting the product by using a cone stylus. Angleand pitch can be measured efficiently |

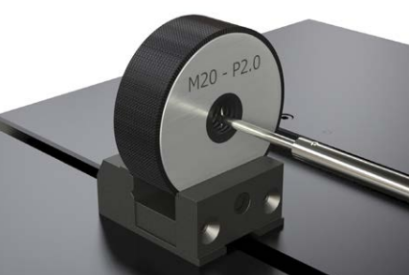

Screw gauge Ring measurement

Upper/lower surface continuous measurement and measurement adjustable feature on the C-4500 detector allows simultaneous measurements of the effective diameter of screw or ring gages, together with thread angle and pitch. Since a part-program (automatic measuring program) for measuring and analysis can be created, effective diameter, which requires high accuracy in micrometer threads, can be accurately and efficiently measured.

|

|

Golf club face Groove form measurement

Groove pitches, groove intervals, and edge shapes are strictly determined by golf club standards. By using the part-program (automatic measuring program) as a standard feature and automating analysis, efficient evaluation is possible with precision measurement. |

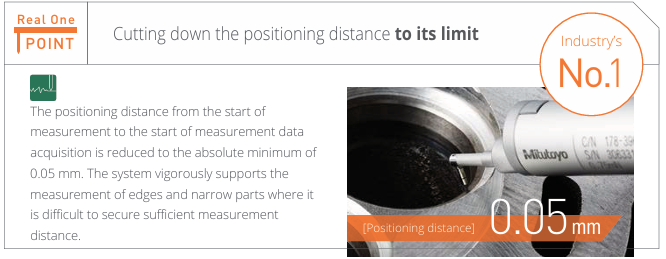

Surface roughness test for tooth faces of gears

The surface roughness of gear teeth may affect strength and torque transfer efficiency. By using a stylus for gear teeth, it is possible to measure over the full face of a tooth, right down to the root. FORMTRACER Avant Series, which can cut off the positioning distance to its limit (0.05 mm) helps evaluate the surface roughness of gear teeth. |

|

Can Pull-top groove measurement

If the pull-top groove is too shallow, the pull-top cannot be opened,and if it is too deep, it will be opened easily, resulting in leakage during transportation due to vibration or shock. The groove dimensions of products can be efficiently controlled for measured where high accuracy is required |

Surface roughness test for tablet molds

Durability is required for tablet molds to ensure the detachability of pharmaceutical powder and reduction of production cost. FORMTRACER Avant Series, which can cut off the positioning distance to its limit, helps evaluate the surface roughness of molds with accuracy and precision as it can measure products with high accuracy from edge to edge |